The vision becomes method

The experience and skills developed by Bonomelli in over 100 years of history today enable the company to boast an in-depth know-how when it comes to its main product, chamomile, and to follow every phase of the pathway “from field to cup.” Its control over the supply and production chain begins when it selects the most suitable land for growing chamomile.

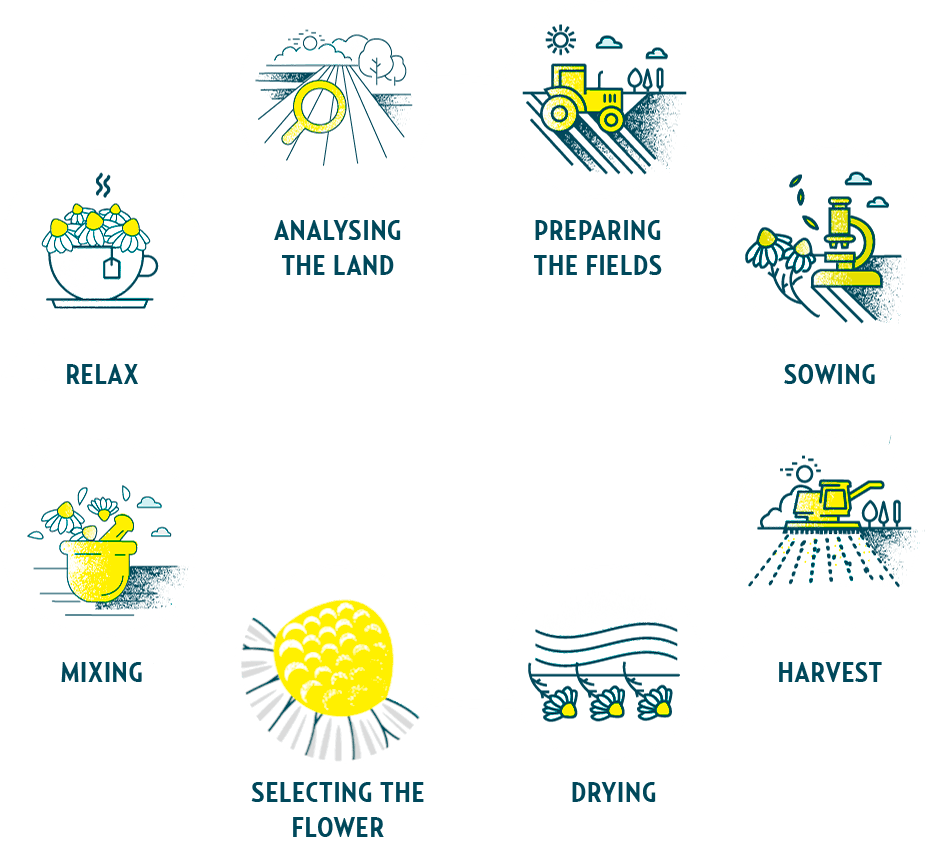

The Bonomelli Chain

Next, it carefully prepares the fields, ensures that the seeds are sown correctly and proceeds to the harvesting, drying, washing, blending and packing phases. A process constantly supervised by the Bonomelli Experts, to guarantee functional products with a unique taste.

Land cames in many shapes and sizes

The company’s constant focus on the quest for quality leads its Agronomists every year to view and select the most suitable agricultural terrains on which to grow its chamomile, in particular, in the fields located in Italy, where Bonomelli oversees all phases of the production

chain, ‘from field to cup’. Each piece of land undergoes a series of analyses, tests and checks which are combined and filed to create the identity card of each field, containing details of: the history of the previous crops, the acidity, the density, the presence of nutrients, the permeability to water. These identity cards are the tools used to evaluate the suitability

of the land, and assess its compliance with the Bonomelli standards. But that’s not all. To preserve the organoleptic and functional integrity of the chamomile flowers, the fields must all be located within a range of 20/25 km from the drying plant, so that the raw materials are processed no later than 2 hours after harvesting.

The Bonomelli Seed

Over 100 years of experience have taught the Bonomelli Researchers to identify – by natural selection – a seed from which a tetraploid chamomile flower is obtained, presenting unique organoleptic qualities. Indeed, this type of chamomile is unique, as it has larger flower heads that are therefore richer in essential oils and offer a drink with an intense scent and an unmistakeable taste.

A gentle respectful harvest

The need to preserve the chamomile flower has obliged the Bonomelli Engineers to design exclusive machinery protected by trade secrets laws.

The Bonomelli “harvesting machines” are unique pieces of equipment, capable of:

– only harvesting whole chamomile flowers to preserve the flower heads, rich in essential oils;

– not damaging the plants, and guaranteeing their natural development so that any flowers that are not yet ready can be harvested at a later stage.

To ensure a gentle, respectful harvest, the machine proceeds at a snail’s pace of maximum 3 km/hour, travelling 3 hectares per day.

Gentle Drying

The chamomile flowers just harvested in the fields located in the Tavoliere delle Puglie, where Bonomelli oversees the entire production chain ‘from field to cup’, arrive at the plant in Foggia, where they are separated from all the green extraneous parts, such as the stalk and any residual pieces of leaf. This is an essential phase, because Bonomelli uses all the parts of the chamomile flower in its products (Filtrofiore and Sifted), without the other natural elements

of the plant.

The most precious part of the flower is then transferred into a unique conveyor oven, one of the many results of the research carried out by the Bonomelli Engineers. The flowers are dried thanks to a continuous flow of air and a respectful temperature that removes the liquid part of the flower, maintaining all its organoleptic and sensorial characteristics intact.

The quest for quality

The need for Bonomelli to have access to chamomile flowers all year round has resulted in a heavy investment in the research and procurement phases of the supply chain. During the chamomile harvesting seasons, the Bonomelli Herbalists visit the crops of selected partners to ensure the raw materials procured are always of an extremely high quality and in line with the Bonomelli standards.

The Bonomelli recipe

All the flowers, now washed and dried, arrive at the plant in Dolzago, in the province of Lecco, where every single batch, identified based on its origin and type, is kept in controlled temperature rooms.

The process continues in the Bonomelli herbal laboratory, where the Master Blenders select, make up and define the correct blend of the various recipes to guarantee the same taste favoured by consumers since the products were launched, balancing the sweet, floral notes with the more bitter, functional ones.

The result in the teabag

The long process ends in the packing phase, where the blend is ready to be inserted into the teabags.

All the ‘know-how’ developed over our years of experience with chamomile is now also applied to our lines of herbal and infused teas too, and it shines through in the careful selection of the best raw materials and in the development of products that stand out due to their combination of taste and functionality.